We provide

Consulting , Design , Commissioning , After-sales service

Consulting

for estimate

- Industry standard

- Data analysis

- Cost planning

- Coordination

- URS

- Validation

- Program translation

- Subject Matter Expert

- Machine vision

Design

with experience

- Function design specification

- Network Security

- Infrastructure

- Panel integration

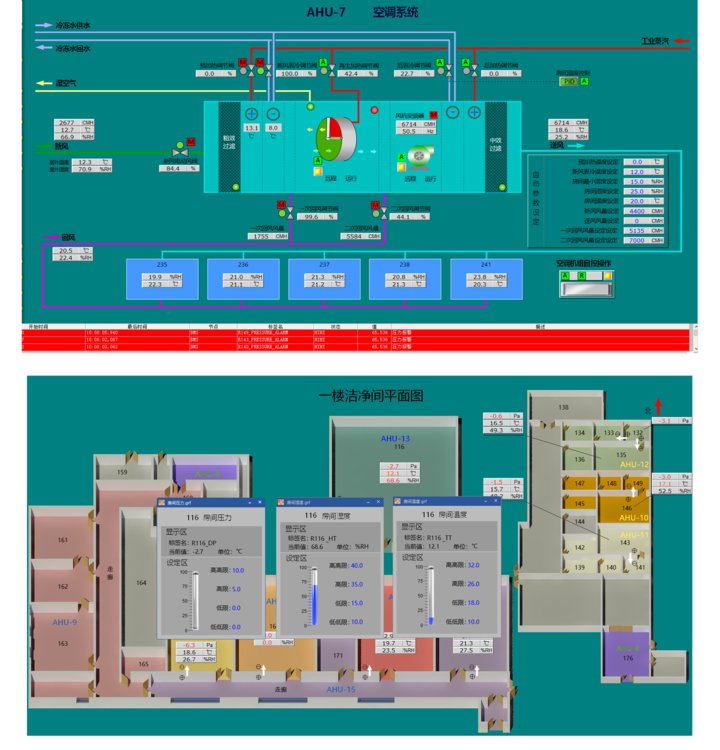

- HMI

- Communication

- CSV for Pharmaceutical

Commissioning

on site

- Project management

- Time schedule

- Delete punch list

- Power on

- Loop test

- Interlock check

- Standard Operating Procedure

- Optimization

- IQ & OQ & PQ for Pharmaceutical

- CCTV analysis

After-sales service

by year

- 7 x 24 On call

- Online maintenance

- Regular visit yearly

- Emergency come within 24 hours in China

- Global fly within 5 days

- Training

Competence in automation

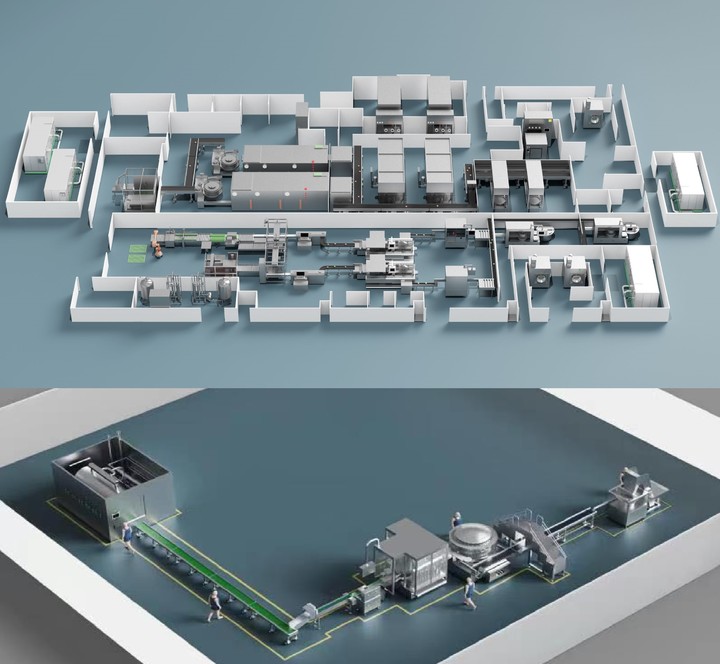

Optimal solution for all industries based on a single platform (one stop shopping)

In-house development and production of all components

Siemens PCS7 as the key point of TIA

Design for detail

From power, netwrok, panel integration to function specification, design is everywhere in you project.

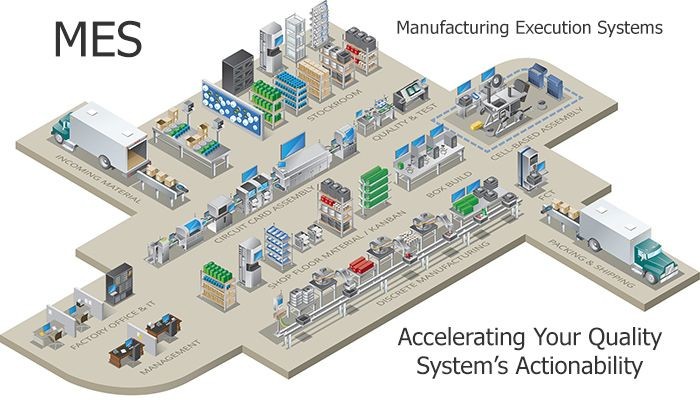

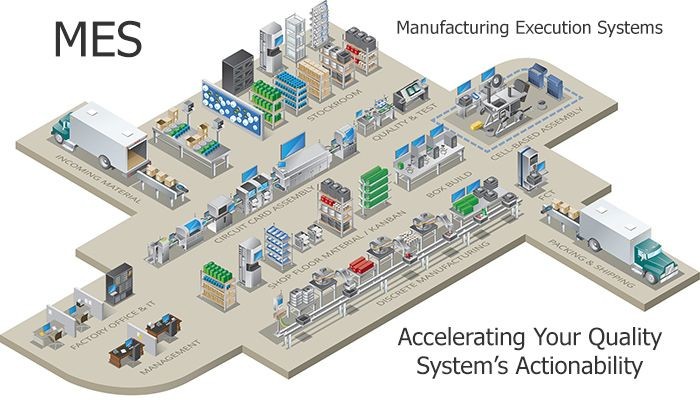

MES

From the production of raw materials to the preparation process, it can meet the requirements of GMP through systematic management.

- Under the requirements of GMP, the linkage between SOP and records and equipment has been realized.

- Prevent human error in business and ensure high quality.

- Standard integration with SAP and ERP

- Flexible response to changes in the database such as new materials and other business changes

- Compliant with Part11, ER/ES

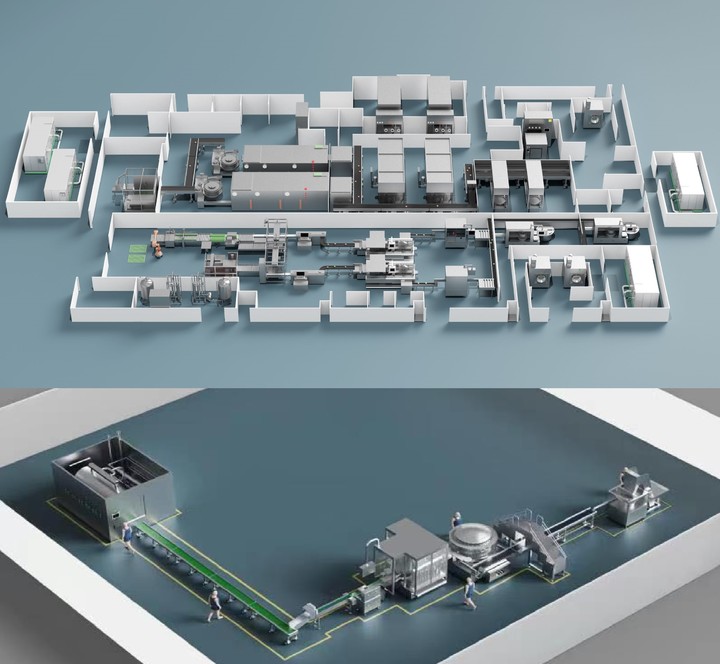

PEMS

Establish an energy management system through advanced automation and information technology to realize automatic, efficient and scientific management of the whole process from energy data collection - energy consumption monitoring - energy consumption analysis - energy optimization.

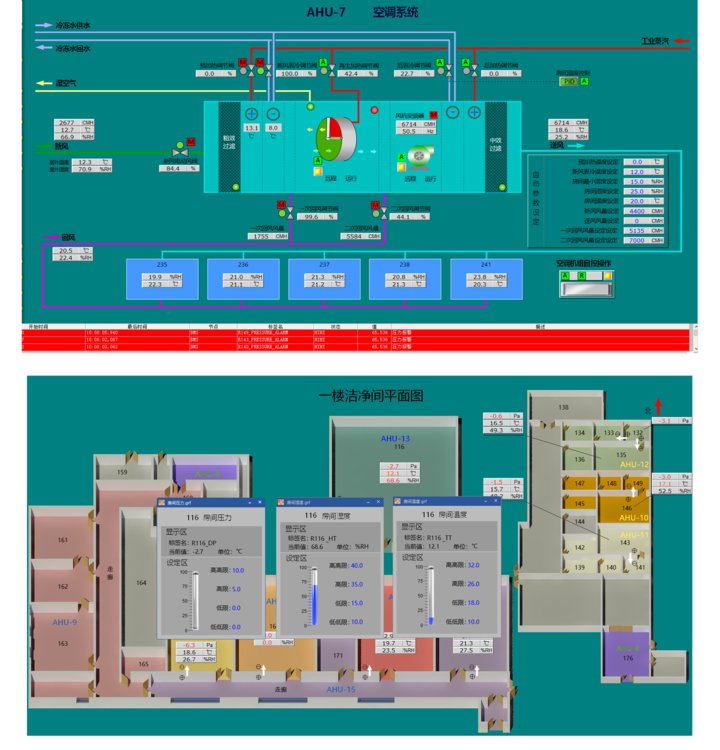

SCADA

Since drugs and substances need to be perfectly consistent across each batch, the monitoring and control of production processes is a must - from processing to transport to delivery. For that, many companies deploy Supervisory Control and Data Acquisition (SCADA) systems.

BMS & EMS

BMS (Good Engineering Practice) Control of temperature, humidity and pressure throughout a facility.

EMS (Good Manufacturing Practice)

Monitoring and historical logging of GMP critical environmental parameters including:

- Temperature

- Pressure

- Particle Counts

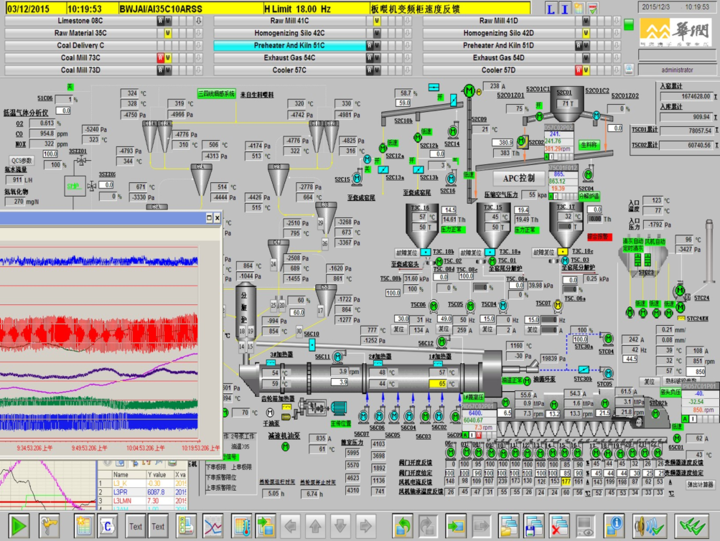

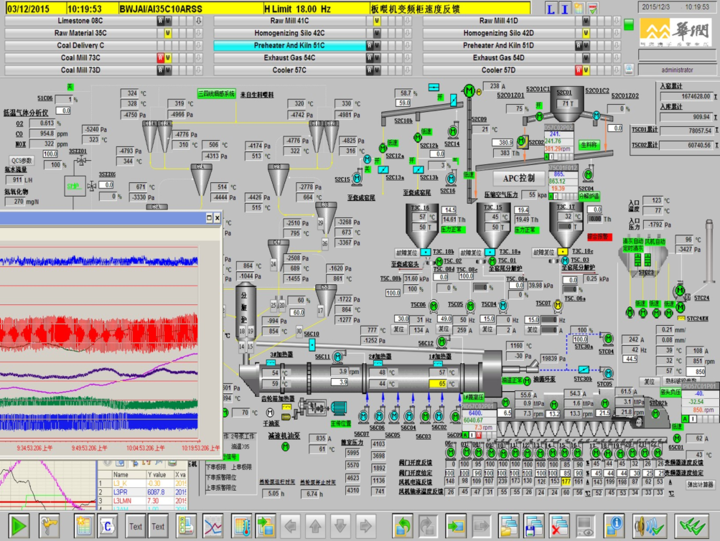

DCS and advanced control

Individually controlling, reporting, and monitoring the components are enabled using integrating distributed control systems with process plants. To manage the database, control logic, graphics, and system security, DCS uses a set of configuration tools. Moreover, it supports modification, upgrade, and integration to the existing architecture of any industry.

© EnergyWit Technology Co., Ltd 2024

E-mail: ew@energywit.com